Txheej txheem cej luam

Qhov xwm txheej:Tshiab

Ntau yam ntawm spindle ceev (rpm):1-30000 rpm

Positioning precision (mm):0.01mm ib

Number ntawm Axes: 3

No. ntawm Spindles:Ib leeg

Lub Rooj Ua Haujlwm Loj (mm):1300 * 1300 hli

Tshuab Hom:CNC Router

Taug kev (X Axis) (mm):1300 hli

Taug kev (Y Axis) (mm):1300 hli

Repeatability (X / Y / Z) (mm):0.01mm ib

Spindle Lub cev muaj zog (kW):7,5 kwv

CNC los yog Tsis:CNC

Qhov Chaw Keeb Kwm:Zhejiang, Suav teb

Hom Lub Npe:GXUCNC

Voltage:380V / 50HZ

Lub zog (kW): 10

Qhov hnyav (KG):3500

Tswj System Hom:NC Studio

Warranty:2 xyoo

Ntsiab Muag Khoom:Siab Rigidity

Siv tau Industries:Cov khw muag khoom siv hauv tsev, Machinery Repair Shops, Manufacturing Plant, Printing Shop, Constructionworks, Energy & Mining, Other, Advertising Company

Machinery Test Report:Muab

Video tawm-kev tshuaj xyuas:Muab

Warranty ntawm cov khoom tseem ceeb:2 xyoo

Core Components:Tsav

Lub npe:Engraving tshuab

Chaw ua haujlwm:1300 x 1300 mm

Spindle ceev:0-30000rpm / min

Kev ceev ceev:10m / min

Tsis muaj kev mus ncig ceev:18m / min

Chaw ua haujlwm:1300 x 1300 mm

Kis hom:TBI

Tswj qhov system:NK 300

Lub tshuab nqus tsev tsis zoo siab twj tso kua mis:2.2 kwm

Khoom Paub meej

| Chaw ua haujlwm | 1300 x 1300 mm | Rov ua qhov tseeb qhov tseeb | ±0.01mm ib |

| Tag nrho spindle zog | 7,5 kwv | Tsav lub cev muaj zog | Servor Tsav |

| Kev ceev ceev | 10m / min | Qhia rail | Taiwan siab precision qhia rail |

| Kev ua kom raug | ±0.01mm ib | Hom kis tau tus mob | TBI high precision txhuas ntsia hlau |

| Spindle ceev | 0-30000rpm / min | Fais fab mov | AC380/50Hz |

| Npuag mus ncig ceev | 18m / min | Tswj System | WEIHONG NK 300 |

| Lub tshuab nqus tsev tsis zoo siab twj tso kua mis | 2.2 KW TSI | NW | 3500 Kg |

Ob Chav Lead Screw Automatic Tool Hloov Engraving Tshuab

F9-1313 ATC yog ib qho tshiab ob chav ntsia hlau hlau ua tsim thiab tsim Engraving tshuab los ntawm gxuncc (Guangxu CNC).Nws tsuas yog siv tooj liab phaj nyem carving, aluminium qhov rooj thiab qhov rais carving thiab lwm yam ntaub ntawv.Lub kaw lus txhawb nqa eng, NC thiab lwm hom ntawv.Kev txiav yog qhov tseeb, yooj yim thiab siv tau.

Tshuab Advantage

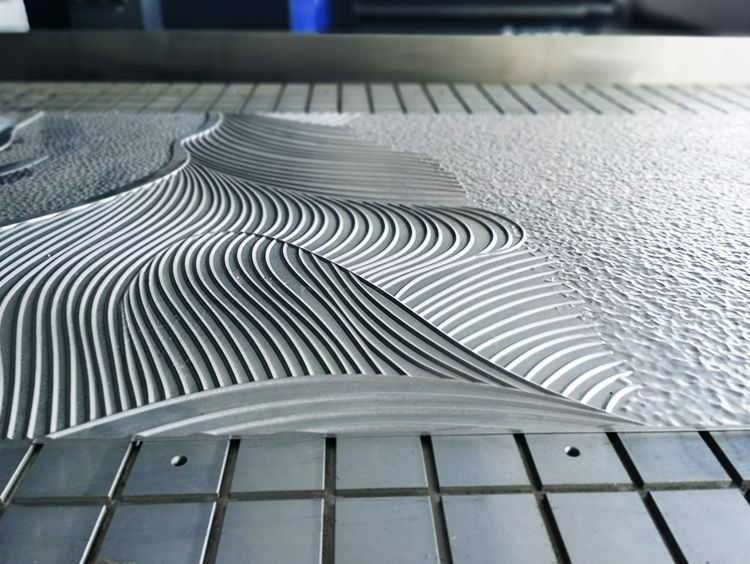

1. Qhov no yog cov cuab yeej ua haujlwm siab, tsim nyog rau cov khoom ua haujlwm nrog ntau tshaj ib lub cuab yeej thiab kev txiav thiab carving siab.Tsis muaj duab ntxoov ntxoo rau hauv qab thiab tsis muaj kev vibration ntawm sab ntawm lub workpiece.

2. Weihong NK300 muaj kev tswj hwm kev lag luam yog ib qho tshwj xeeb kev lag luam tswj kev ua haujlwm, uas muaj kev ua haujlwm nrawm dua;

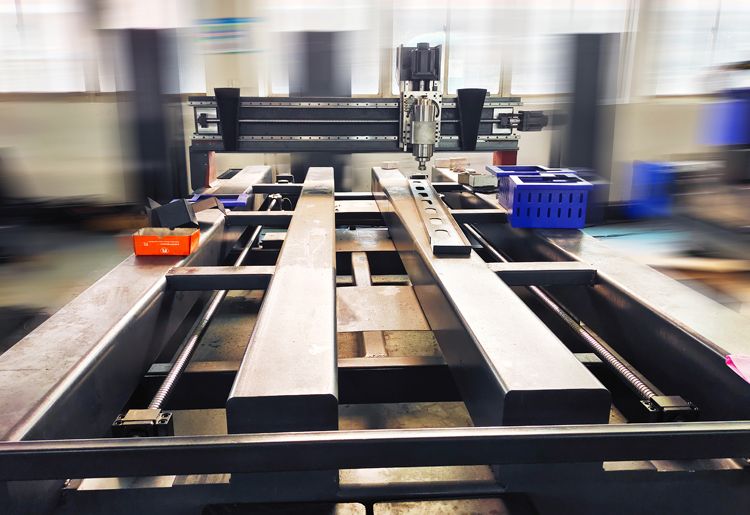

3. Lub tshuab hnyav yog 3.5 tons, thiab qhov kev ntxhov siab raug tshem tawm los ntawm kev lag luam vuam tempering los xyuas kom meej tias lub txaj yuav tsis deform rau lub sijhawm ntev, thiab cov machining precision yog ntau ruaj thiab cov kev pab cuam lub neej ntev dua;

4. Imported servo lub cev muaj zog, zoo precision thiab ruaj khov; txhuas lub tshuab nqus tsev adsorption rooj nrog T-hom fixture tooling, los xyuas kom meej lub firmness ntawm lub workpiece mus rau qhov loj tshaj plaws;

5. Lub 7.5kW high-power twj hloov spindle yog nruab nrog 4 lub cuab yeej magazine, uas muaj ntau dua automation thiab ceev efficiency;

6 . Tsis siv neeg hloov cuab yeej.

Khoom Qhia

Nws muaj cov dej ntws tawm, uas tuaj yeem txuag tau dej

Lub rooj aluminium tsis yooj yim rau deform thiab muaj siab precision

Siv WEIHONG NK300 kev tswj hwm kev lag luam.

Kev ntxhov siab raug tshem tawm los ntawm kev lag luam vuam tempering kom ntseeg tau tias lub txaj yuav tsis deform rau lub sijhawm ntev.

Hlau tooj liab phaj nyem thiab txhuas phaj qhov rooj thiab qhov rais carving nrog siab precision.

lubrication system ua rau lub tshuab tu yooj yim dua.

Los nrog lub npog plua plav kom tsis txhob muaj plua plav.

Lub tank saw yog muab faib ua compartments, cov kab yuav tsis entangled ua ke.

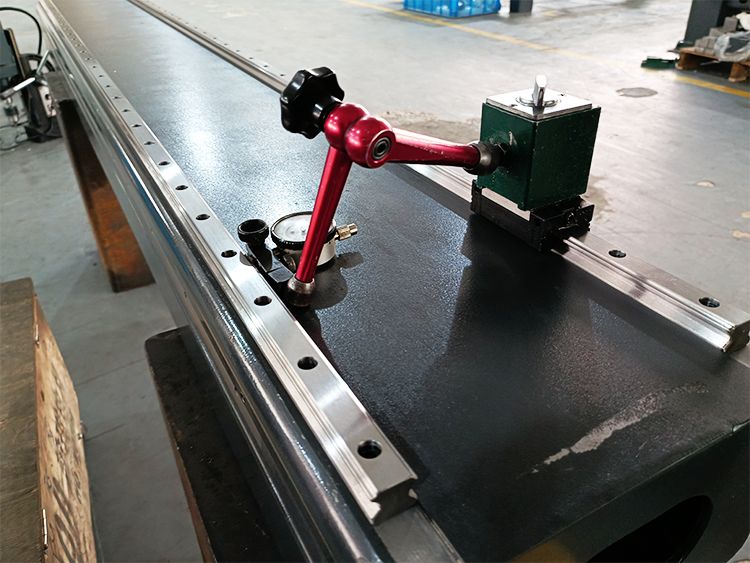

ntsia hlau ruaj ruaj, siab precision, loj load bearing thiab ruaj khov khiav.

Nruab nrog lub tshuab nqus tsev twj.

Lead ntsia hlau thiab qhia rail parallelism calibration.

Ail parallelism calibration

Qhov Rooj Qhia

1.100%.

2.100% cov qauv kuaj, uas yog, txhua lub tshuab tau raug kuaj los ntawm cov qauv ua ntej xa khoom;